Heat Transfer Film

Heat transfer films are sophisticated materials used to print colorful designs, logos, and graphics onto clothing and apparel. Heat transfer films are typically made from tough plastics like PVC, polyurethane (PU), or BOPET (biaxially oriented polyester), heat-transferred and pressed onto the garment.

Types of Heat Transfer Films

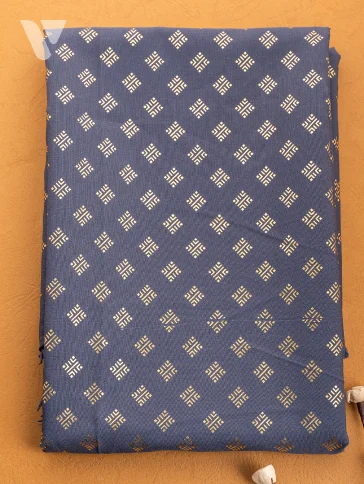

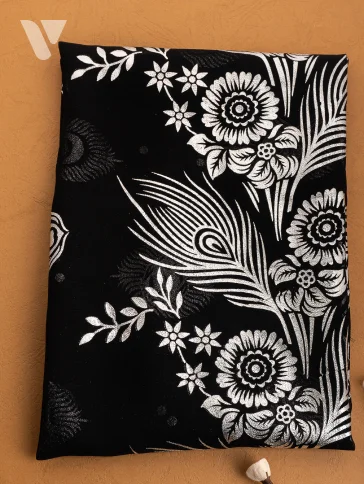

- PVC and PU Films: Employed for T-shirt printing and are available in different finishes and colors.

- BOPET Films: Known for their clarity, durability, and chemical, water, and tear resistance. Suitable for complex, detailed patterns and suitable for multiple uses in textiles.

Key Benefits

- Durability: Heat transfer films, especially BOPET, are highly abrasion-resistant, machine wash-resistant, and weather-resistant. Designs remain vibrant and intact even after multiple washes.

- Moisture and Chemical Resistance: These films are resistant to most chemicals and repel moisture and are thus applied to outdoor wear, workwear, and sportswear.

- Wrinkle and Dimension Stability: Heat transfer films will not wrinkle or become distorted, giving a crisp, professional appearance on clothing.

- Versatility: Perfect for printing on cotton, polyester, blends, bags, shoes, home decor, etc. They can accept a variety of printing processes, including CAD lettering, screen printing, offset, and digital printing.

Why Use Heat Transfer Films?

Heat transfer films give clothing manufacturers a uniform, flexible, and affordable method of using high-quality, durable graphics on a wide range of fabrics. Convenience, as well as increased durability and design freedom, makes them a number-one pick for custom and mass apparel production.

Aesthetic Diversity: Available in glossy, matte, metallic, and satin finishes, so designers can achieve the appearance they desire for any garment.