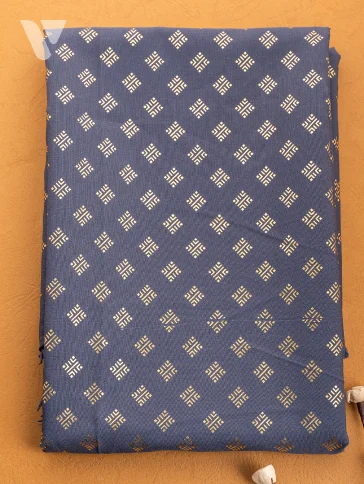

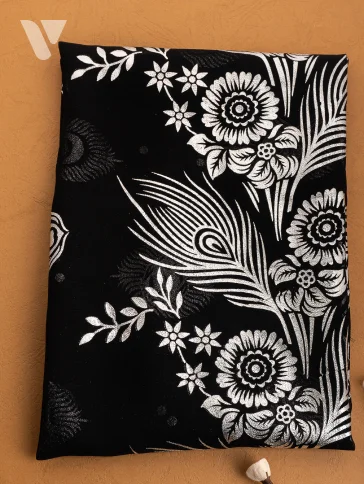

Hot Stamping Foil Printing

Foiled hot stamp printing is a proprietary dry printing method employing pressure in conjunction with heat, in tandem with metallic or colored foils, to transfer successfully a preferred design onto a material such as fabric or leather material. With regard to more traditional ink-based printing processes the average individual will be familiar with, the newly devised process uses a film in the form of a foil to permit direct transference of finish and color onto the material desired, hence dramatic visual effect.

Key Elements Foil Film is made up of several layers:

- Polyester base layer (carrier)

- The release layer allows the carrier to be removed from the foil.

- Colour layer, metallic or pigment.

- The adhesive layer adheres to the substrate.

- Or one plate and die: Made of such material as brass, magnesium, or silicone.

- Does the design or pattern have to be shifted.

Hot Stamping Machine

- Apply controlled pressure (20-100 psi) and controlled heat (usually 100-200°C) to activate the adhesive and to transfer the foil.

- Step-by-Step Detailed Procedure: Design Engraving: A special die is specially engraved with the particular pattern or logo that has been chosen for the specific purpose.

- Foil Placement: The placement of the foil itself is in the space that is between the die and the fabric.

- Stamping: Pressure and heat for a certain dwell time (1-5 seconds).

- Foil Transfer: The adhesive is triggered, and the foil sticks only where pressure is applied.

- Peel-Off: The carrier sheet is removed slowly and gently from the surface, leaving a clear and sharp reflective print.

Different kinds of Hot Stamping Foils:

- Metallic Foils (Rose Gold, Gold, Silver, Copper)

- Holographic Foils (Rainbow effects, 3D illusions)

- Pigment Foils (matte, gloss, transparent)

Textured Foils (Brushed metal, leather-like) Hot stamp foil print creates a dramatic, high-end look that maximizes the visual impact of apparel. It is appropriate for branding, limited runs, and statement products where cut and impact are crucial. Its eco-friendly, clean process and rapid drying make it a favorite with high-end apparel producers and niche brands.