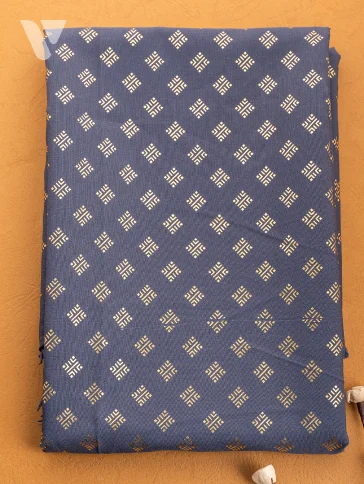

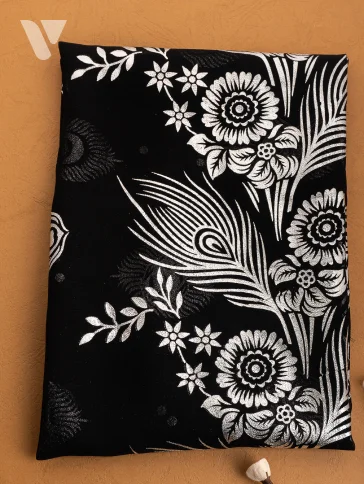

Water Transfer Films

Water transfer films, or hydrographic films or immersion print films, are specialty printed films that are engineered to transfer fine designs, patterns, or textures onto different surfaces, such as fabric, using water as the medium. The technique is valued for its ability to achieve smooth, complete coverage decoration on flat or oddly shaped objects.

Benefits of Water Transfer Films in Apparel Building

- Seamless Coverage: Water transfer films also have the ability to enhance complicated shapes and surfaces, making them suitable for apparel with irregular shapes or three-dimensional features.

- Design Variety: Patterns ranging from wood grain, marble, camouflage, and custom graphics can be obtained, thereby enabling very creative and distinctive textile designs.

- Customization: Simple to change films for alternative appearances, thus suitable for limited editions or customized clothing.

- No Heat Required: In contrast to heat transfer procedures, water transfer printing utilizes water and chemical activation and is thus compatible with heat-sensitive materials.

Limitations and Considerations

- Durability: Water transfer prints are not as wash-resistant as heat transfer prints, so strict adherence to care instructions would be necessary to preserve the look of the design over time.

- Equipment Required: Needs dipping tank, activator spray, and occasionally a clear coat to top.

- Best Applications: Most appropriate for fashion items, accessories, or embellishments where special surface effects are needed and where the shape or texture of the garment makes the other transfer techniques less convenient.

Why use Water Transfer Films?

Water transfer films give garment manufacturers the flexibility to produce visually striking, all-over patterns that are difficult to achieve with other printing technologies. Their ability to conform to complex shapes and to deliver a wide variety of patterns makes them a precious tool for innovative fashion and textile design.